Socialist Romania Computer Chips

The socialist bloc of countries that arose after World War II was not a monolithic entity, it had significant country and cultural differences. A number of countries stood apart, one of them was socialist Romania. The leadership of Romania pursued a relatively free domestic and foreign policy, while remaining within the framework of the socialist system and being a strategic ally of the USSR and a member of the Warsaw Pact.

Through the CMEA (Council for Mutual Economic Assistance), the USSR assigned Romania the role of a supplier of agricultural products. The “big brother” proposed to mothball the agrarian backwardness of the republic, which did not suit Bucharest at all. In the late 60s, Romania chose to stand on the path of intensive industrialization. Hydroelectric dams block the Carpathian rivers, and then the Danube. Light industry plants work at their maximum capacity – thus, the country becomes the largest exporter of textiles in Europe. Enterprises of ferrous and non-ferrous metallurgy, chemical and petrochemical, and furniture industries were built. The extraction of precious and non-ferrous metals, uranium, oil, gas, coal were developed intensively. Since the early 1970s, Romanian enterprises have been producing large numbers of machine tools, turbines for power plants, cars, locomotives, tractors, combines, trucks, and household appliances. In the summer of 1979, Romania bought a license from British BAE Systems to produce the BAC 1-11 passenger jet. It was produced at the purpose-built Romaero plant in Bucharest. In total, under Ceausescu, 9 Rombac 1-11 planes were built.

At the beginning of the 1980’s, there were two entities in Romania that produced electronic components, IPRS and ICCE

IPRS-Băneasa, Bucharest. By the early 1980s, the company had over 6,000 employees and nine production facilities. It was located on 15 hectares (37 acres) of land on the edge of the Băneasa forest near Bucharest. Products (capacitors, diodes, analog and digital ICs, thyristors, transistors) were sent not only to the countries of the socialist bloc, but also to Asia and Western Europe.

IPRS-Băneasa, Bucharest. By the early 1980s, the company had over 6,000 employees and nine production facilities. It was located on 15 hectares (37 acres) of land on the edge of the Băneasa forest near Bucharest. Products (capacitors, diodes, analog and digital ICs, thyristors, transistors) were sent not only to the countries of the socialist bloc, but also to Asia and Western Europe.

|

|

|

ICCE (Research Institute of Electronic Components) was built outside the premises of IPRS-Băneasa, but in close proximity. In 1979, the micro-production department of the institute was opened. From that moment on, ICCE was able to supply many of the components developed at the institute, namely those that were requested in relatively small quantities (thousands per month) and which IPRS-Băneasa did not produce because it was not economically viable. Thus, it can be said that ICCE was not a real competitor for IPRS-Băneasa, but rather an addition. For example, in the 1980s, so-called special programs appeared, required electronic components for the Oltcit plant, for the heavy water plant in Turnu Severin, for the nuclear power plant in Cernavodă, as well as for the army. These components were needed in relatively small quantities, with harsh operating conditions carefully selected through reliability programs.

ICCE (Research Institute of Electronic Components) was built outside the premises of IPRS-Băneasa, but in close proximity. In 1979, the micro-production department of the institute was opened. From that moment on, ICCE was able to supply many of the components developed at the institute, namely those that were requested in relatively small quantities (thousands per month) and which IPRS-Băneasa did not produce because it was not economically viable. Thus, it can be said that ICCE was not a real competitor for IPRS-Băneasa, but rather an addition. For example, in the 1980s, so-called special programs appeared, required electronic components for the Oltcit plant, for the heavy water plant in Turnu Severin, for the nuclear power plant in Cernavodă, as well as for the army. These components were needed in relatively small quantities, with harsh operating conditions carefully selected through reliability programs.

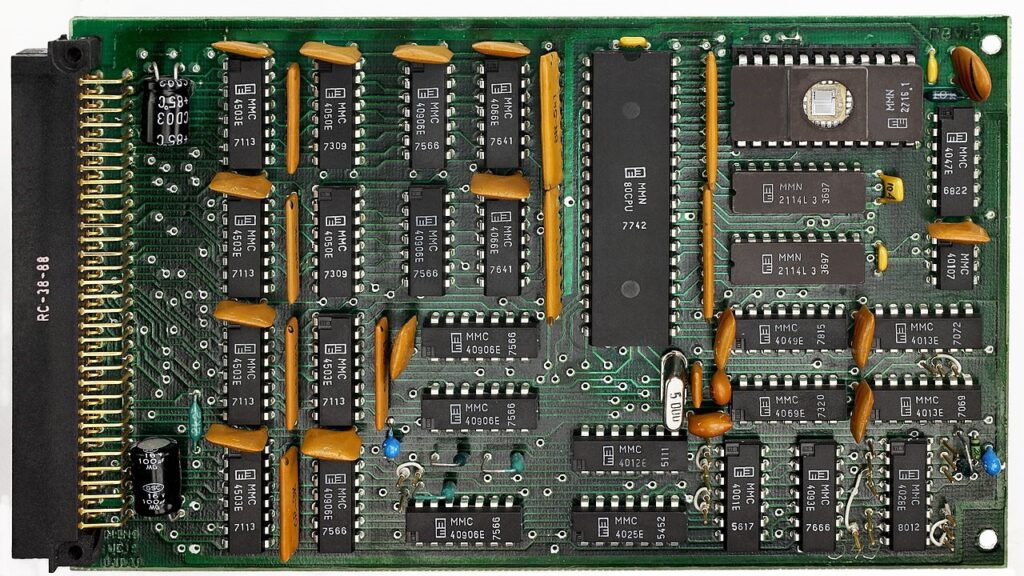

But a third entity that appeared later is of much interest to us, Microelectronica (ME) was set up in 1981 close to I.P.R.S. and ICCE with the goal of manufacturing PMOS, NMOS, and CMOS integrated circuits as well as optoelectronics, complementing the production profile of I.P.R.S. At its inception, ME had about 40-50 employees, most of them engineers, representing the Microelectronics group at ICCE.

But a third entity that appeared later is of much interest to us, Microelectronica (ME) was set up in 1981 close to I.P.R.S. and ICCE with the goal of manufacturing PMOS, NMOS, and CMOS integrated circuits as well as optoelectronics, complementing the production profile of I.P.R.S. At its inception, ME had about 40-50 employees, most of them engineers, representing the Microelectronics group at ICCE.

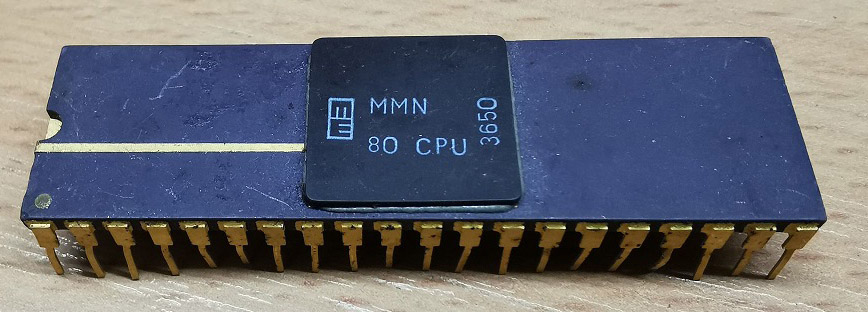

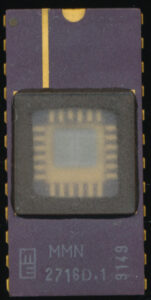

It was at Microelectronica that CPU, RAM, ROM chips were produced, used in computers and controllers. Unlike the Soviet integrated circuit designation or the East German semiconductor designation, the Romanian government did not set standards for the labeling of semiconductors. Devices licensed from Western manufacturers were often named according to the Pro Electron standard. Microelectronica assigned integrated circuit designations according to the underlying technology:

|

|

|

| MMP for PMOS | MMN for NMOS | MMC for CMOS |

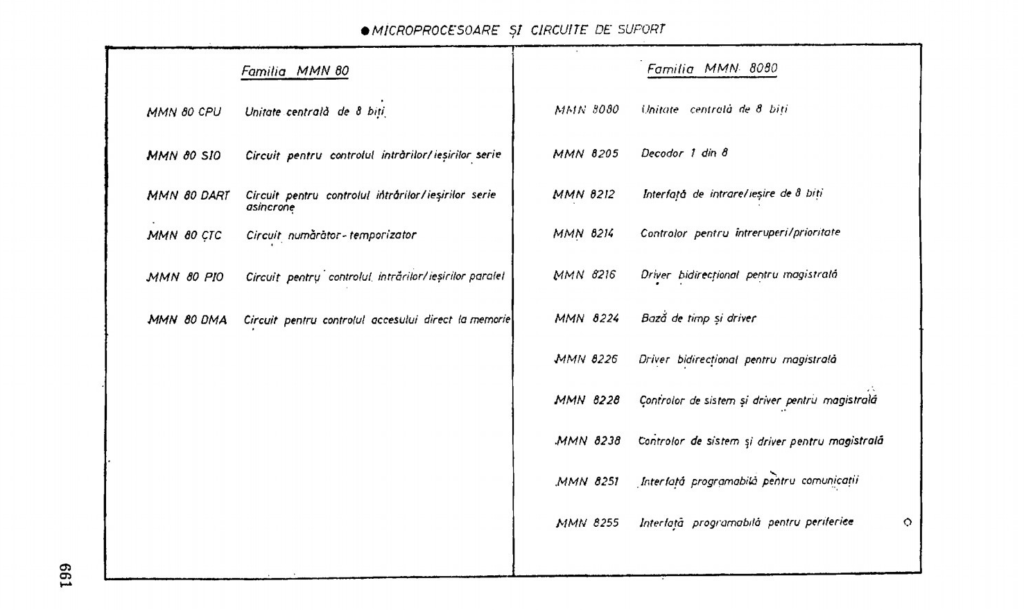

Here is the page from the combined 1989 catalog of all three entities. As we can see, Microelectronica by this time had mastered the production of two microprocessors MMN80CPU and MMN8080 with support/peripheral chips.

|

|

| MMN80CPU- clone of the Zilog Z80 | MMN8080 – clone of the Intel 8080 |

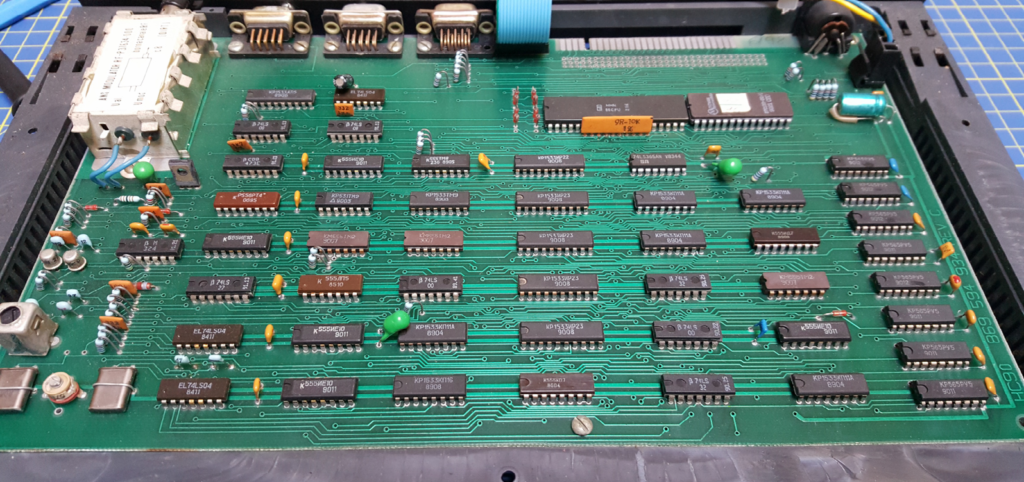

The MMN80CPU was the heart of numerous Romanian clones of the ZX Spectrum ( COBRA, CIP series (Electronica București), ICE-Felix production models).

It was also used in various industrial controllers, in particular in controllers for controlling weaving machines (supporting Romania’s textile industry).

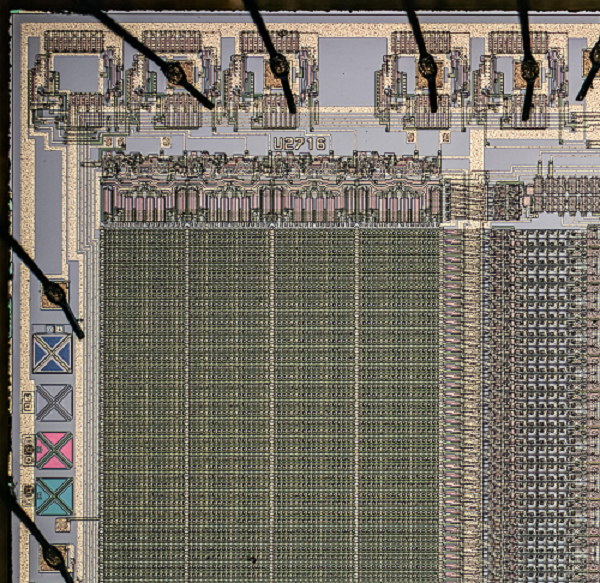

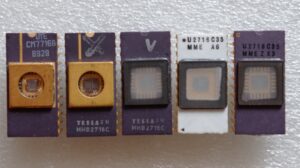

At the same time, along with microprocessors, the production of UV-EPROMs was launched. These were Intel 2716 clones.

Noteworthy is the case of the microcircuit, which is atypical for the electronic industry in Eastern Europe.

|

|

| UV-EPROMs from East Europe | UV-EPROMs from the USSR |

As we can see, nothing similar to the MMN2716.1 package is observed.

But there is a striking resemblance to the UV-EPROMs that Texas Instruments made years earlier. By the time the MMN2716 was released, TI had long since switched to making higher capacity chips. These chips require packages with more pins due to the increase in addressable inputs. And TI warehouses have unclaimed packages that were likely sold as surplus

|

|

| MMN 2716D.1 from 1991 | Mostek MK2716T-8 from 1979 |

MMN2716 was also produced in another package, similar to the package in which Mostek UV-EPROM chips were produced earlier (only a slight difference in Pin 1 markers). Given the close ties of the Romanian electronics industry with the Italian SGS-Ates (later SGS), which acquired Mostek in 1981, this is not surprising.

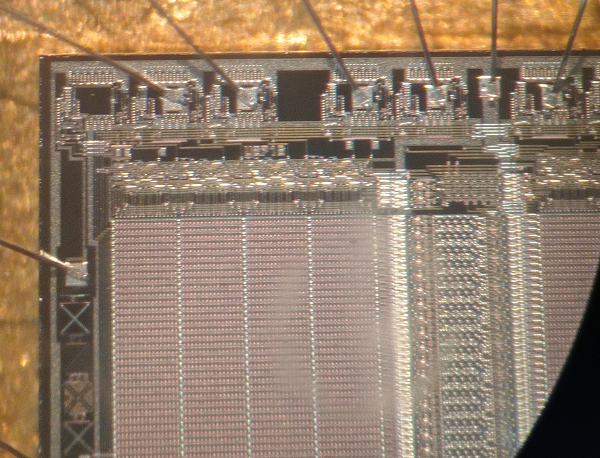

Now let’s look inside. Unfortunately, there is only one MMN2716 in my collection. And I’m sorry to open the chip. So I tried to take a photo of the die through the quartz window.

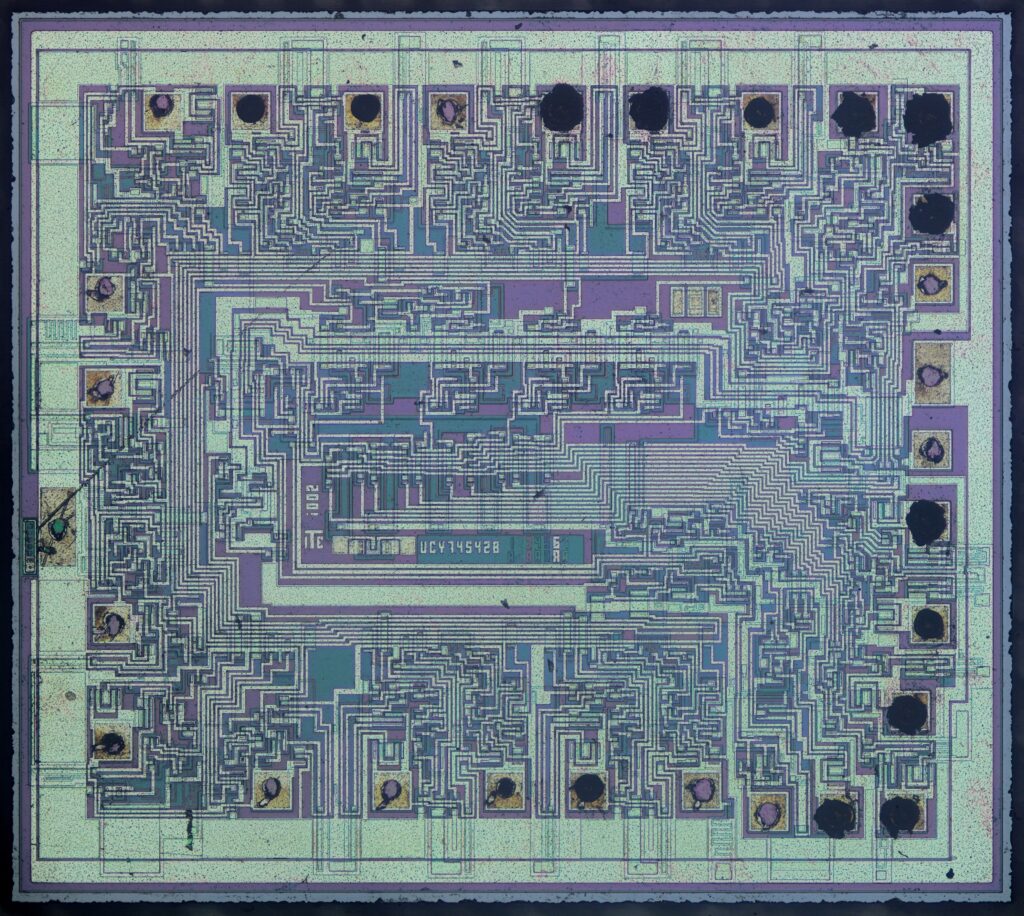

And here is the dieshot of the U2716C35 MME from East Germany.

It is impossible not to notice the complete identity of the dies MMN2716.1 and U2716C35.

MBD8238. System controller and bus driver. Intel 8238 clone, manufactured in Schottky Bipolar technology.

But inside it has a UCY74S28 die-Polish clone of Intel 8228. It’s strange that it’s not an Intel 8238 clone.

The difference between i8228 and i8238 is the formation of IOW, MEMW signals. i8228 generates these signals relative to the WR “Write” signal, and the i8238 microcircuit generates these signals relative to the STSTB “Status Strobe” signal. i8228 can be replaced with i8238, but vice versa, i8238 with i8228 is already problematic.

But before we draw any conclusions, let’s take a brief course into history.

Romania financed the development of the economy in 60-70 using revenue gained from the export of oil products and grain, as well as obtained through Western loans. As a result of the 1973 oil crisis, oil prices jumped sharply, and the flow of money from oil-producing countries to Western banks increased several times over. This, in turn, has produced an excess of money, which led to the credit rate plummeting to 1-2% per annum and banks began to massively lend to countries, including those from the social camp. This allows Romania to accumulate more loans to buy technology and licenses from companies from the United States and Western Europe, as well as build factories and modernize the agriculture sector.

And then it was the debt burden that caused the big problems. By the end of the 70s, oil prices had stabilized, major transformations have begun in the Middle East, and some of the money began to be invested locally. The loan taken under floating interest was rising its price right before their eyes. Since 1976, the interest rate has been growing by 1% per year, and in the summer of 1979, it reached 11.2%. Until 1979, the largest supplier of oil to Romanian plants was Iran, who exchanged it through barter for Romanian goods at a firm, market-independent price. But in 1980, the revolutionaries who overthrew the shah refused to barter and began to demand US dollars for their oil. Romania now faced a problem: how to load its refineries and simultaneously sell the products of engineering plants? In addition, in the early 1980s. problems arose in the oil industry – it became apparent that there was a depletion of oil reserves. In 1980, the Romanian government was tasked with paying off creditors for the next ten years. The country has introduced tough austerity measures. Romania sharply refuses to import products and consumer goods – only what is necessary for Romanian production is imported.

Everything Romanian that could be sold abroad was exported. About 85% of finished textiles, 88% of shoes, 93% of gasoline produced in the country were exported. In 1987, Romania ranked 12th in the world in terms of exports. In 1981, Romania introduced a card system for the issuing of most products and everyday goods. Gasoline was rationed at a rate of 30 liters per month per passenger car. The consumption of electricity in everyday life was limited (it was forbidden to use a refrigerator during the winter, and the use of a vacuum cleaner was banned all year round), hot water was supplied to apartments twice a week, television worked 2-3 hours a day. An era of total deficit was coming for a country that experienced a sharp social rise in the 60s and early 70s.

The production of microprocessors and support chips got somewhat restored and launched only in 1988, although it was impossible to count on their export potential at that time. Most likely, the products were intended for the domestic market. With the economy in such situation, it is difficult to imagine a launch of an enterprise such as Microelectronica, which provides a full cycle of chip production at this point. Photolithographic and other technological equipment, electrochemical deposition systems, washing chambers, laboratory oxidizing chambers, copper electrodeposition systems – all of this is very expensive. Most likely, the company only packed silicon obtained from the countries of the Eastern Bloc. Otherwise, how can it be explained that inside the Romanian chips are crystals developed in Poland and East Germany. Although, of course, it is possible that the in-house production of chips used photomasks developed in Eastern Europe.

In any case, the release of Z80 and i8080 clones, support and memory chips has long been mastered in the socialist countries, and there was no need to reinvent the wheel.

There was also no in-house production of ceramic packages for chips. All of the ceramic packages in which Romanian chips have been found were of Western origin. This is not surprising though, if we were to recall the foreign policy pursued by Ceausescu during those years.

Here are a couple of important facts:

1979 – Condemnation of Soviet intervention in Afghanistan

1982 – Start of construction of a Romanian nuclear power plant with Canadian CANDU-type reactors instead of Soviet ones

1984 – Ignoring the Soviet boycott and the participation of Romanian athletes in the Los Angeles Olympics.

In an effort to alienate Romania from the Eastern Bloc countries, Western European countries and the United States gave various benefits to the Ceausescu regime. And the ceramic packages were simply given to Romania as further encouragement.

This article does not claim to be the truth in the last instance, many assumptions are hypothetical in nature. It is only an attempt to look at history from a certain angle. If you have additional information, please do let us know.

References:

Electronics industry in the Socialist Republic of Romania https://en.wikipedia.org/wiki/Electronics_industry_in_the_Socialist_Republic_of_Romania

Microelectronica SA, from the formation of the team (1976) to the peak moment (1990)

https://www.electrokits.ro/en/microelectronica-s-a-de-la-formarea-colectivului-1976-la-momentul-de-varf-1990/amp/

THE THEFT OF ROMANIA. IPRS Băneasa, bought at a luxury car price and with false documents

https://www.digi24.ro/special/campanii-digi24/romania-furata/romania-furata-iprs-baneasa-cumparata-la-pret-de-masina-de-lux-si-cu-acte-false-257599

Electronic Components Research Institute

http://nini.qsl.ro/node/732

Photo of MBD8238 die is from the website: http://radiopicture.listbb.ru/index.php.

Author: Vlad

Edited and some pics by The CPU Shack