The 6502 Travels the World: The Story of the Indian SCL6502

India in the 1970’s was often considered a third world county, supported by a largely agrarian economy and with a wide swath of the population still based off of subsistence living. They also however, had a robust space program, had mastered nuclear technology and had a largely stable government that supported the advancement of technology development in the country. All the pieces were there to begin making the shift to the robust high tech economy that they possess today. In the 1970’s India had several govt entities working on semiconductors and electronics, all managed under the direction of the Dept of Electronics. There was also a fair number of companies with plants in India doing electronics manufacturer and assembly. This was largely small scale production of older technology. TTL circuits (starting with the 7420) were made in Bangalore by BEL back in 1971. But TTL circuits won’t get you far, and at that time the best process India had was around 8 microns, so in 1972 an initiative was started to develop an indigenous semiconductor industry within India.

Politics are the same everywhere, and so this process took some time, people with experience had to be recruited to run it, and a suitable (politically and geographically) location selected. Eventually in the late 1970’s the Semiconductor Complex LTD was formed in the city of Mohali ( Chandigarh ) in the Punjab province of India. SCL was to be the state supported enterprise to bring indigenous high end (LSI and above) semiconductor production to India. Two things were needed to make this work: Technology, and People who were experts in that field. SCL was tasked with going to Japan, America, and Western Europe in search of a company that would assist with the technology transfer, as well as finding some Non-Resident Indians who would be willing to come back to India to work on it. Many Indians had high skill jobs in the industry outside of India, and it turned out convincing them to come back to help their country was a non-issue (though generous incentives were provided). Getting the technology on the other hand was a bit more work.

The first trip of the technology transfer team of SCL was to Hitachi in Japan. Negotiations with Hitachi were grueling, and while not unproductive, did not yield the results SCL wanted. Hitachi was happy to license some designs to SCL, for a high fee and royalties, but did not want to immediately help create the 3-5 micron production fab that SCL envisioned. Hitachi called thei ‘one step at a time’ whereas the Indians wanted to go all in from the start. Hitachi agreed only to help (some) with a 5 micon process) and only to license products for digital clocks and watches. The SCL team then turned to the United States, likely expecting similar results.

The chosen company in the USA was AMI (American Microsystems Inc), a company with 7-8 times the turnover of Hitachi. AMI was at the time the largest maker of custom ICs in America, as well as a very large provider of second source ICs (such as the 6800 and 9900 CPUs). AMI’s CEO Roy Turner readily agreed to help SCL, much to the surprise of their negotiation team, and on the very first day offered SCL AMI’s 5 micro CMOS and NMOS processes, with the option to license their 3 micron CMOS and NMOS processes within 4 years of the agreement becoming effective. AMI also offered SCL access to all of AMI’s standard products catalog, as well as the possibility of joint development of additional products, all at a simple 50/50 split. AMI even offered to help with the technology export license that would be required by the US State Dept to transfer the fab tech to India. The agreement was signed in April of 1981.

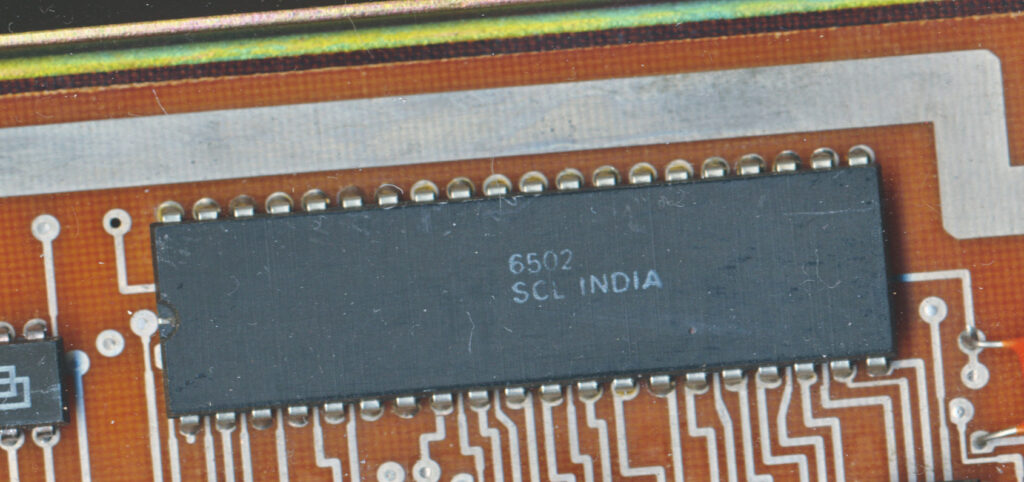

By October of 1983 SCL had a 4″ (100mm) class 100 5 micron fab up and running, based on AMI technology, and were already making LSI circuits. The first chips made were telecoms chips (tone pulse dialers) from AMI. Telecoms was the main focus of the enterprise, as building a country wide telecommunications network in India was of paramount importance. You simply cannot develop a high tech economy if you have no way to communicate rapidly. These digital telecoms required a digital processor to control them, and thats something that SCL did not yet have, and something AMI couldn’t license them (the AMI 6800 was licensed from Motorola so could not be transferred by AMI to SCL). In 1984 SCL purchased a license from Rockwell for the 6502 CPU, the 6522 and the 6530 and began production of these on their 5 micron NMOS process. This is what became the SCL6502 CPU.

The SCL6502 found wide use in Indian Telecoms equipment but also in some interesting computers. In 1984 the BBC Micro 2 computer was licensed for production in India as the SCL Unicorn. These were made with chips from SCL, 6502 CPU 6522 VIA and 6530 RIOT except the proprietary ULA. By 1988 3600 of these computers had been built and supplied to schools in India, with a goal of 250,000 by 1990.

SCLs goal was to supply domestic Indian needs, as well as hopefully supply some export market. Lack of investment hampered the second goal, with costs of SCL chips often higher than other sources due to smaller production runs and equipment that wasn’t as modern as other competitors world wide. This pushed SCL to work with ‘closed’ markets, specifically the Eastern Bloc

In 1973 the Santacruz Electronics Export Processing Zone (SEEPZ) was created in Mumbai to facilitate the export of electronics. In August of 1974 the Electronic Trade & Technology Development Corporation (ETTDC) was created to fully exploit the immense possibilities of mutual trade and cooperation between India and the USSR. The ETTDC not only worked to export Indian products and knowhow, but also find lower cost imports from the USSR and Eastern European Countries. By 1984 India was exporting $155 million worth of electronics (8.2% of their production). In the late 80’s initiatives continued to help foster this export. In July of 1987 a Science and Technology cooperation agreement was signed with the then USSR to help facilitate import/export of high tech devices to and from the Soviet Union. This resulting not only in trade of products, but of expertise, with Soviet and Eastern European (specifically workers from Pravetz in Bulgaria) assisting at SCL in India. Due to various sanctions and embargos, the USSR had less options for importing then other countries, so even if SCL’s prices were higher than others it was better then not being able to. India was able to walk a useful middle line between the East and the West being immune to the CoCom sanctions of Eastern Bloc countries.

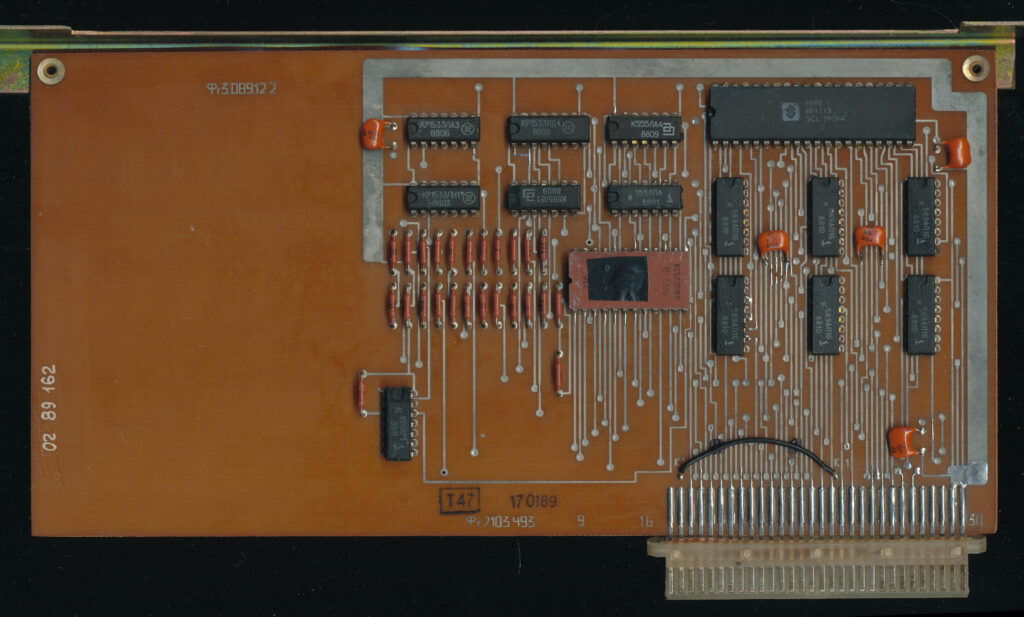

It is through this agreement, and the ETTDC that India began supplying the USSR with SCL6502 processors. The Soviets had designed a series of computers, inspired by the Apple II called the AGAT 7 and AGAT 9 that ran on a 6502 processor. These are commonly found with Rockwell processors (Likely imported via India) as well as SCL produced 6502 processors. The USSR never developed their own NMOS 6502 (they did make a very few CMOS 6502s however), relying on imports larley from India for the processors of these computers.

Some of the SCL6502 CPUs used on the AGAT appear to be sanded down and remarked. These very well may be remarked Rockwells

In one ironic twist of international politics, when the UN Industrial Development Organization sought to help North Korea by providing them a fab in 1980 they could use to make ‘commercial’ products, they selected India, via the ETTDC to build it, as Western companies were prohibited from doing so by CoCom sanctions. This reliance on a captive market ultimately led to the failure of SCL to greatly succeed at exports as they were limited to working with these Eastern Bloc countries, being unable to compete with Western companies due to being behind on a cost and technological level. When the Eastern Bloc collapsed, so did most of their market.

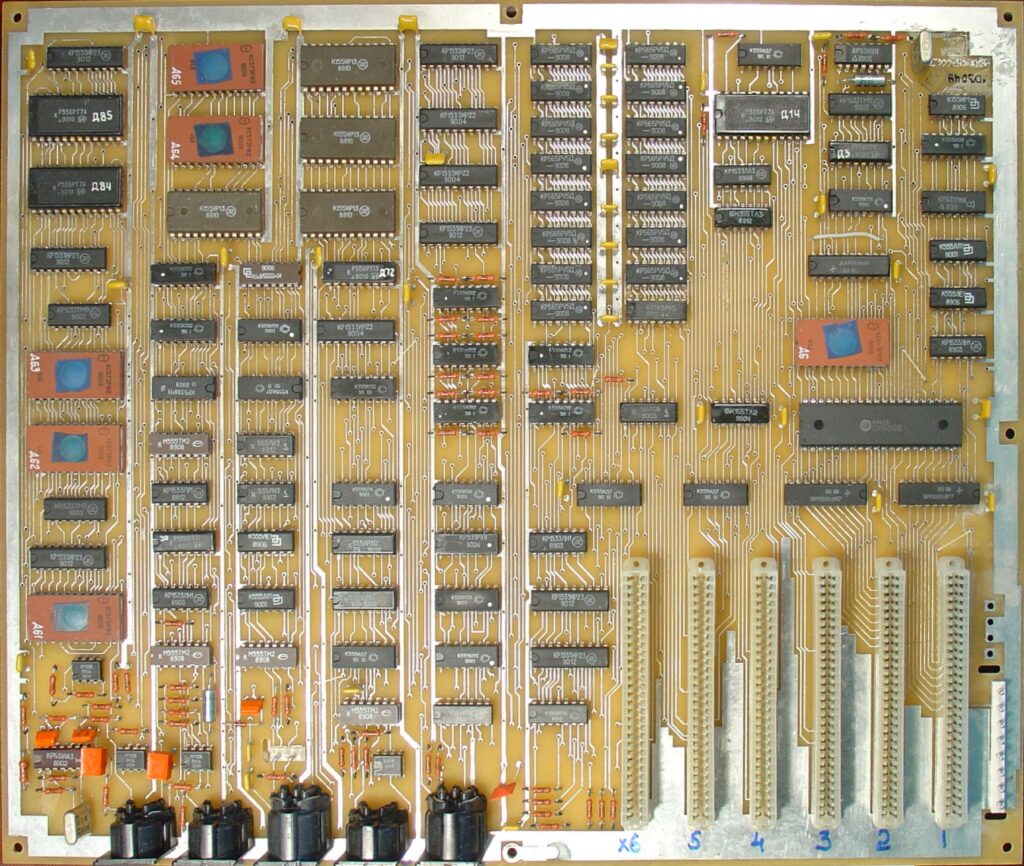

AGAT 9 Motherboard – CPU in this case is a UMC6502. UMC was based out of Taiwan so would have been allowed to export IC’s as to India and/or the USSR

SCL then developed its own 3 micron processes in house (not needed to purchase them from AMI) and moved most of their telecoms production to this process. Its unclear if they moved the 6502 line to 3 micron or not. By 1989 SCL had numerous products in production, many of them of strategic importance, both for telecoms, and the Indian Space agency (ISRO). And then… disaster struck….

On the night of February 8th 1989 a electrically fire started, destroying the entire SCL fab. One can of course rebuild a fab, but in the mean time what was SCL to do? Their products were of critical importance to many Indians agencies. An agreement was quickly hammered out whereby SCL would port their processes and production to Austrian Micro Systems in Vienna Austria to ensure production while the fab was rebuild. Sometimes a disaster can be a blessing, or an opportunity, and in this case SCL used it as an opportunity. They build the fab back, bigger and better. Replacing the old 100mm class 100 fab with a 150mm (6″) class 10 fab capable of producing chips down to 1.2u. The problems of lack of investment continued, with the rebuilt fab not opened until 1997 by which time 1.2u was nearly 10 years out of date. By 2000 the fab was upgraded to 0.8u and then 0.6u, but still, always on the trailing edge of technology. SCL’s revenues in 1999-2000 were about $14 million, not significantly more then they were making in the 1980’s,

SCL is now part of the ISRO (Indian Space Agency) and continues to supply high reliability chips (now down to 0.18 micron using technology from Tower Semiconductor in Israel) to critical industries in India. Recently (2017) they developed their own in house processor (the 16 bit Vikram 1601) to replace aging 68000 processors for on board computers on ISRO rockets.

In many ways SCL was a huge success, bringing high tech to India, and allowing them to supply their needs indigenously. In other ways, however, SCL was a bit of a failure, perhaps disappointment is a better description. There was a great hope of ‘Make in India’ and send all over, SCL was to be the foundation of not only making things in India, but exporting them worldwide, and while this occurred some in the 1980’s, today SCL is a boutique fab making specialized chips almost solely for the internal use of the ISRO and related agencies. Today India is home to many many design and engineering centers for other companies though. Many products are designed, and engineered in India, and exported around the world, but ironically, few are actually made there. Perhaps then the greatest success of SCL, was in the human talent that it returned to India.